Torque converters, Irrespective of their strong development, usually are not proof against use and tear. Quite a few variables can contribute to their deterioration and eventual failure. Let’s take a look at some of the common culprits:

In higher efficiency, racing and large duty professional converters, the pump and turbine could be even more strengthened by a system referred to as furnace brazing, through which molten brass is drawn into seams and joints to make a much better bond involving the blades, hubs and annular ring(s).

A design attribute as soon as present in some Standard Motors automated transmissions was the variable-pitch stator, during which the blades' angle of attack may very well be diverse in reaction to modifications in engine speed and cargo. The outcome of this was to vary the amount of torque multiplication made by the converter.

In many scenarios, the failure of the vehicle’s torque converter clutch solenoid will lead to a number of shift-linked abnormalities.

The Charge of the oil tension in the lock-up clutch is completed by two valves: the relay valve and the sign valve. In this type of arrangement the signal valve controls the stress on just one aspect on the relay valve, which controls the tension during the lock-up clutch. By default, equally valves are stored into placement by springs, leaving the clutch within the disengaged posture along with the torque converter unlocked. When increased line force is placed on the decrease Section of the signal valve, it moves up and connects the road pressure to your relay valve decreased finish.

Once the car or truck pace will increase from sluggish to substantial, the need for mechanical positive aspects decreases as well as equipment ratio in the torque converter gradually alterations to that of the fluid coupling. It's so because the turbine pace steadily strategies the pump velocity.

The following are several of the most typical signs affiliated with torque converter solenoid failure.

Labor charges for this restore might be fairly higher, mainly because it will involve removing the transmission to accessibility the torque converter. This can add Yet another $four hundred to $700 to the whole bill.

Some automated transmissions characteristic single-phase torque converters. They're a more straightforward kind of the conventional torque converter. They are lighter and a lot more compact given that they have only one particular established.

After the oil has been pushed against the turbine blades, it should get again for the impeller so it can be utilized all over again. (Not like our lover analogy, where by We now have a place packed with air, the transmission is really a sealed vessel that only retains much oil.) That’s where by the stator is available in.

The torque converter will allow the motor to idle once the automobiles is stopped Despite the fact that the transmission has a equipment engaged. Given that the title implies, the torque converter converts (amplifies) the Sumber input torque in the motor into an increased output torque. This specific aspect with the torque converter is not possible using a clutch, that may transmit highest the engine torque rather than more than that.

Switching from the solenoid causes the stress to extend on the proper facet in the regulator valve, which is able to go to your remaining. This operation will reconfigure the oil circuit in such a way that the oil will flow through the rear of the clutch, closing it.

Inside the shut posture, the torque converter clutch reduces fluid shipping towards the torque converter, allowing for controlled slippage to happen.

In case the torque converter is defective, it would make unpredicted pressures inside the torque converter, which could cause tough idling.

Jonathan Taylor Thomas Then & Now!

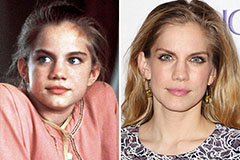

Jonathan Taylor Thomas Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Batista Then & Now!

Batista Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!